Preparatory steps before production

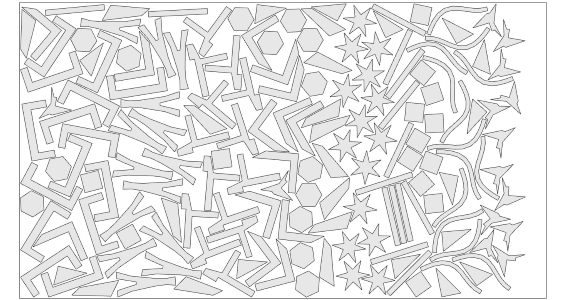

RhinoNest allows you to optimize any type of geometry using a variety of options to make it as easy as possible, such as multi-paneling, using real or rectangular shapes, priorities between objects, and more.

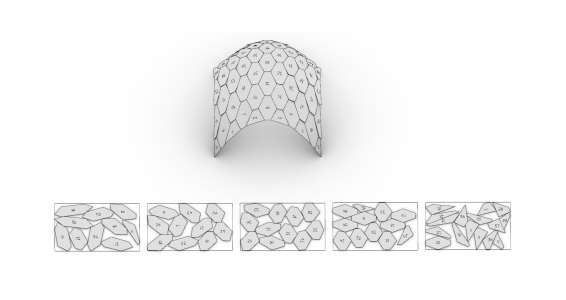

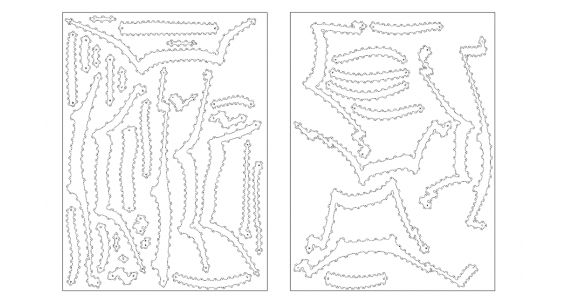

Stages of nesting

- Display slices in 3D objects

- Defining multiple panels

- Placing slices in CPIane for further optimization

- Slicing Surface, Solids and Mesh

- Auto detect snippets, text and/or plain text tracing

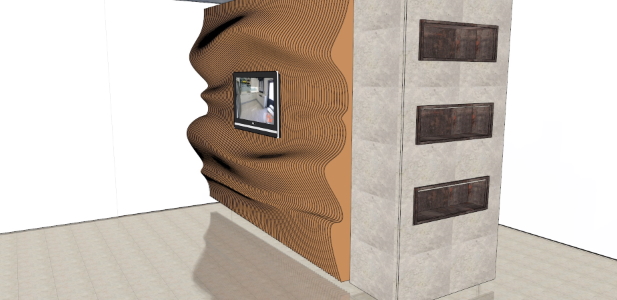

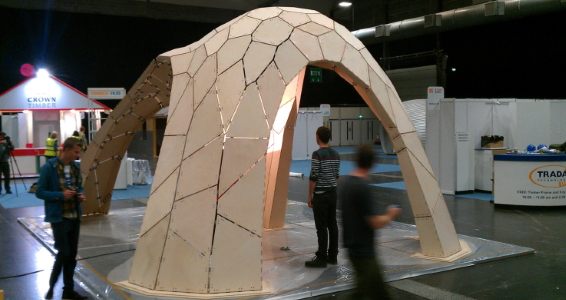

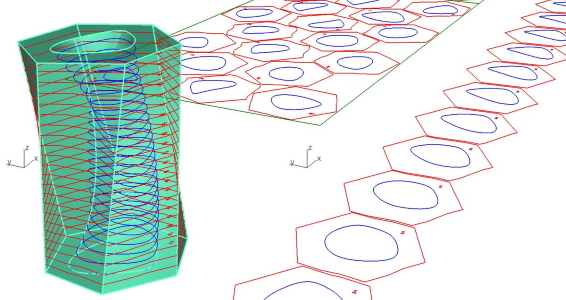

3D cutting for laminating 3D objects

3D cutting allows you to laminate 3D objects for laser or CNC cutting.

The element reassignment function automatically identifies each part when flat rolling.

Integration with Grasshopper

Grasshopper is a graphical algorithm editor tightly integrated with Rhino’s modeling tools. Unlike programming tools, Grasshopper does not require programming or scripting knowledge. However, it gives designers the ability to create form generators from the simplest to the most complex.

RhinoNest for Grasshopper contains the same interface tools as Rhino.

Selecting a graphic object

- Detect object copies

- Finding multiple priorities between objects and determining placement order

- Free rotation

- Optimization options when copying a single object

Defining Panels

- Using one or more panel sizes

- Have a centralized panel database, ideal for large production runs

- Defining a panel by material, size, quantity in stock and SKU

- The fill bar option ignores the number of objects and uses as many copies as needed to fill the bar

Options

- Space between parts

- Distance between parts and panel limits

- Max optimization time. Heuristic algorithm to calculate different solutions before displaying the best one

- Rectangular shapes that allow you to influence the calculation using a minimum number of rectangles for each object

Reports

- Display a list with panel number, number of items per panel, used area, and free area to control optimization

- Copy values to clipboard to paste into any application

- Export report in text format

Working with Rhino technology

RhinoNest is fully integrated and designed for Rhino and therefore provides optimization in minutes without the need to import files from other software. RhinoNest supports all types of geometry, eliminating the need for transformations.